Support Us To Create More Content By Share or Like to Download:

We all know that squeeze plastic tubes packaging is one of the most low costs, efficient and durable & stable packaging for cosmetics product. Today, we are gonna talk about it how to choose its specification of plastic tube for your cosmetic brand tailored.

Table of contents

The plastic tube shape in shape optionThe shape be round tubethe shape is oval tubeSpecifications of plastic tube sleeve designMatrix of capacity and diameter in plastic tube volume.In round shape plastic tube sleeve item dataIn oval shape plastic tube sleeve item dataPlastic tube printing artwork area designsWorking on die line for artwork designArtwork design process.Designing cosmetic tube artwork have to know thisCapping procedure and sealing end tube considerationThe compound of tubing choiceTwo layers of plastic tube sleeveFive layers plastic tube sleeveThe option of closure cap style for regular round plastic tube Bread style capFat-angled screw-on capStraight-angled screw-on capRegular screw-on capStraight regular flip-top capFat-angled flip-top capScrew on capStraight-angled flip-top capFat-angled flip-top capWith cosmetic pump head itemWith the massager particular application head itemThe closure style for small volume tube optionflat-top lipstick capwith no capbullet caplipstick style capnozzle style cap

The plastic tube shape in shape option

choose the shape of plastic tube shape firstly before start to design. there are mainly 2 type of option:

The shape be round tube

the shape is oval tube

Specifications of plastic tube sleeve design

To map out the specification of plastic tube in the beginning of the design process. It's including capacity, diameter, and length in plastic tube, and cap and closure.

Matrix of capacity and diameter in plastic tube volume.

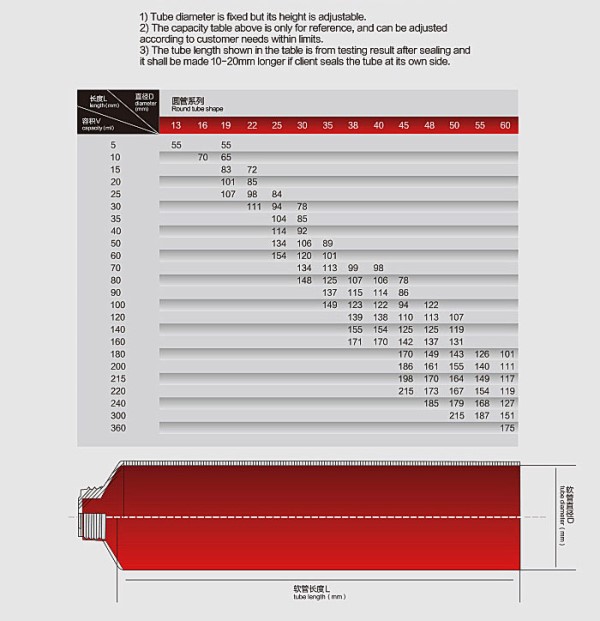

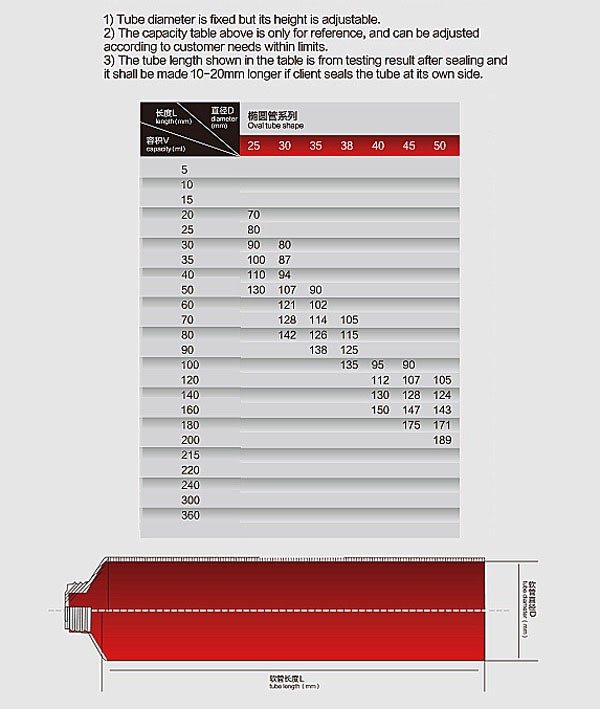

It will use this matrix to calculate the length of the tube. Please be noted that the specification on list are for reference only, and it also can customer size be available by optional.

In round shape plastic tube sleeve item data

Please refer below photo on data in metric you refer to (capacity in ML, diameter in MM, Length in MM)

In oval shape plastic tube sleeve item data

Please refer below photo on date in metric you refer to (capacity in ML, diameter in MM, Length in MM) for oval shape tube sleeve

Plastic tube printing artwork area designs

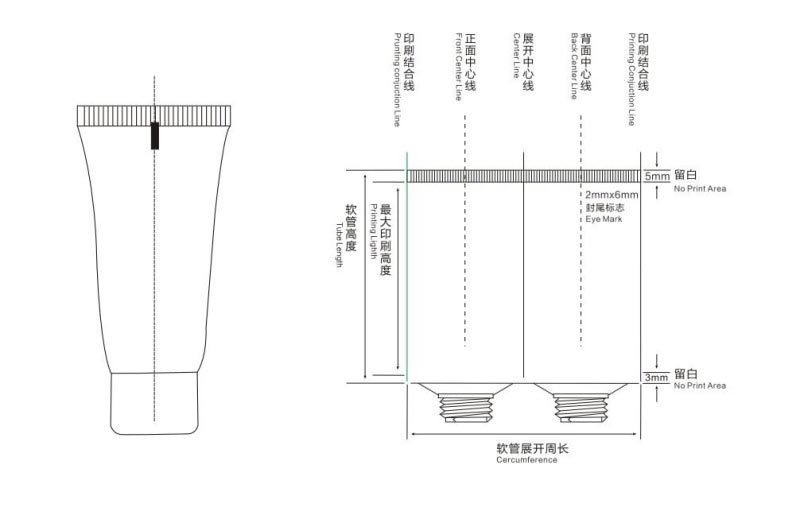

For the artwork printing, it have to draw the die line for artwork firstly.

Working on die line for artwork design

It will be need to create the die line per below design firstly before design branding artwork. If you don't have the professorial designer to create that die line, you can contact us to do this job for you, which it is freebie. Please check link plastic cosmetic tube to leave comment and contact us get die line for your artwork design.

Artwork design process.

The designer will come up with your branding element, product description, usage, information of detail etc. design drawing within the die line, and send the draft for your approval. If your team don't have a packaging designer, it will be needed to consider hiring a contractor to do the graphic designer job.

Designing cosmetic tube artwork have to know this

When it comes to plastic cosmetic tube on design, you have to get these knowledge or concepts:

1>, Product may shrink by 2.0% following production.

2>,1.5 mm must be reserved for circumference printing.

3>, Standard size for eye mark (per blow photo mark location) is 2.0 mm×7.0 mm, other size are available by requested.

4>, No print area next to the tube shoulder is 3 mm, no-print area on the tube tall is 5 mm. Print workmanship can be adjusted according to the requirement.

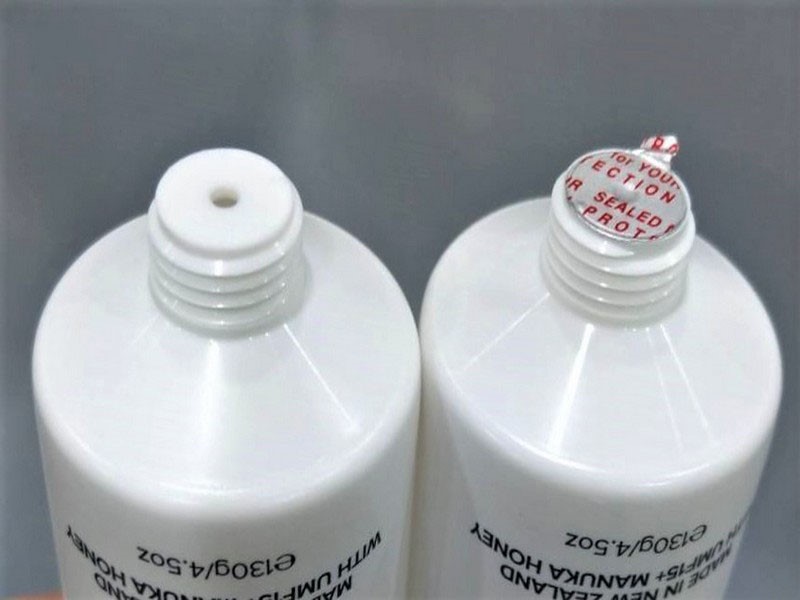

Capping procedure and sealing end tube consideration

On the beginning of design plastic tube, the type of sealing end tube will be need to consideration. Either one of them can work with you, but it will be needed to comply with the filling machine you're existing had and product themselves.

1>for the open end tube item, it will be need to seal the tube sleeve end after filling.

This one needs to get Orifice with Foil Seal, and assemble the plastic tube with cap for customers, so the customers could fill their product from the root and then seal the root by themselves.

2>close end tube item, which it will be need to do the filling on plastic tube orifice.

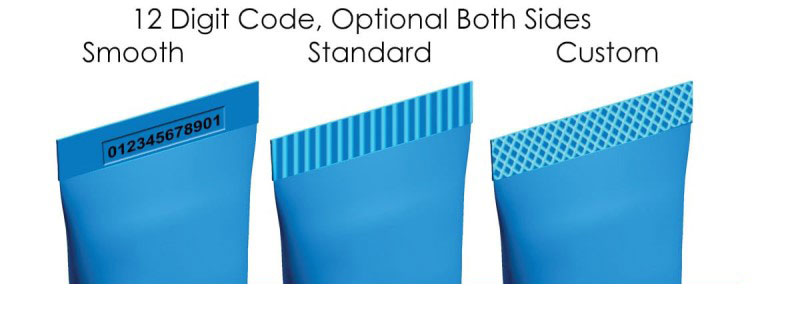

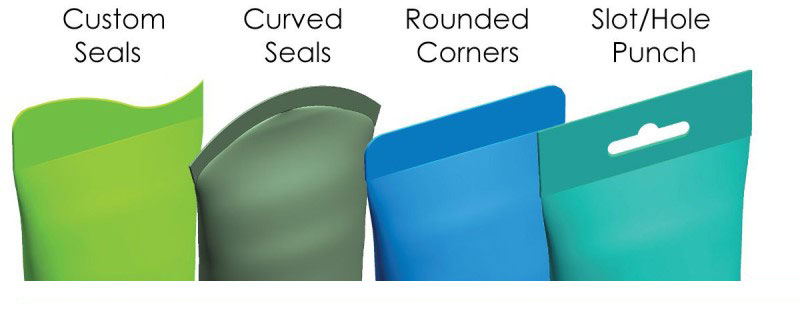

The sealing pattern option of close end tube can be divided into: straight pattern sealing, diagonal pattern sealing, umbrella sealing, star point sealing, special-shaped sealing etc.

And sealing can be required to print the valid date code at the sealing end some time. It will need to check with the branding company or filling factory in advance before run mass production plastic tube.

To control the heater and the clamp very well, which can seal the tube bottom perfectly.

The compound of tubing choice

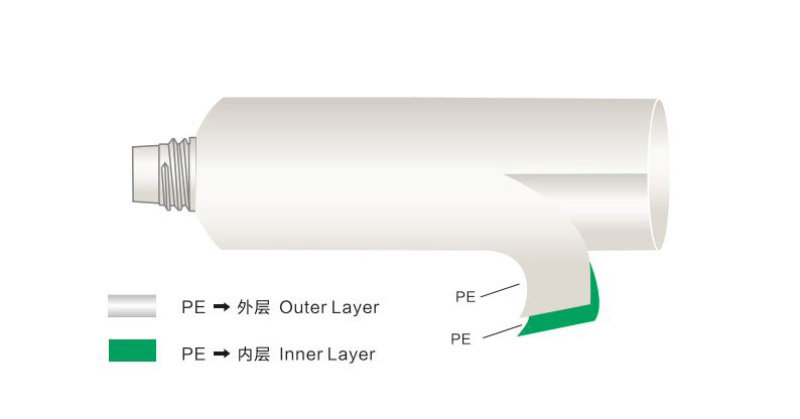

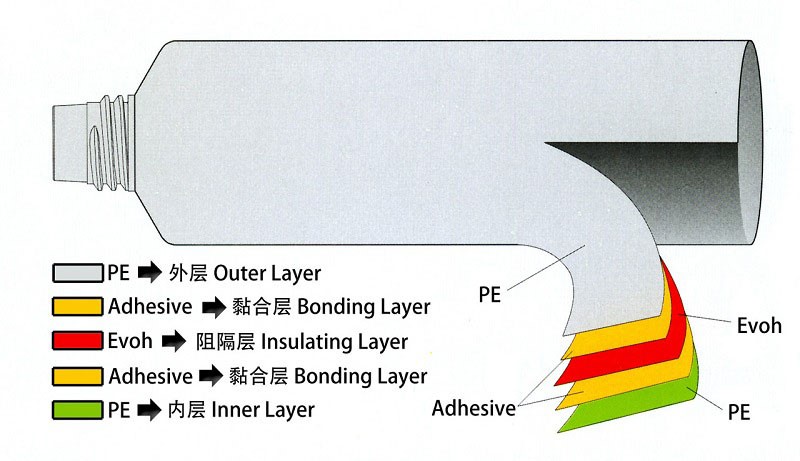

Two layers of plastic tube sleeve

Feature: convenient to use, soft-touch and fine scalability and impact resistance. But as a disadvantage of as bad gas barrier, the dissolved aromatic compounds are easy to be oxidized. It is applied to on cleansing cream, hand cream, facial mask packaging etc.

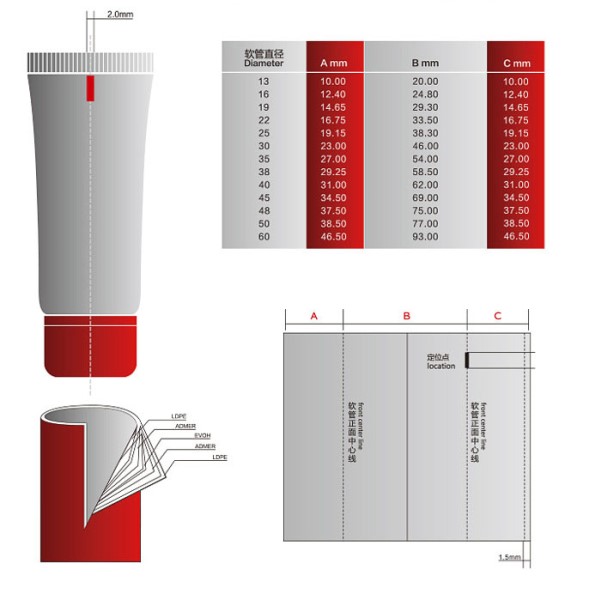

Per below photo for structure for reference.

Five layers plastic tube sleeve

Compared to 2 layer tube, there are much better gas barrier result and toughness, it can be highly to prevent the ingredient from oxygen. It be better recommendation to all kind of packaging products.

DIAGRAM OF FIVE-LAYER COMPOUND TUBING

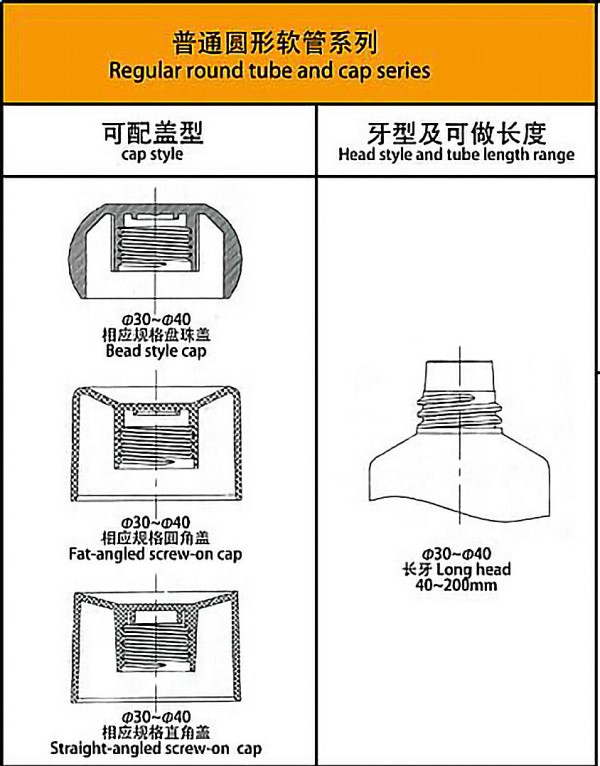

The option of closure cap style for regular round plastic tube

There are so many cap style for plastic tube, below list normal what we see on common item.

Bread style cap

Diameter 30mm-40mm, suitable for Φ30-40mm round tube, long head thread 40-200mm.

Fat-angled screw-on cap

Diameter 30mm-40mm, suitable for Φ30-40mm round tube, long head thread 40-200mm.

Straight-angled screw-on cap

Diameter 30mm-40mm, suitable for Φ30-40mm round tube, long head thread 40-200mm.

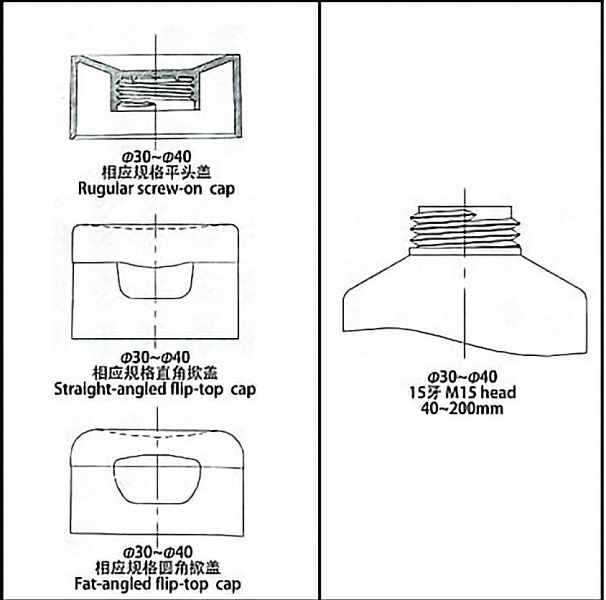

Regular screw-on cap

Diameter 30mm-40mm, suitable for Φ30-40mm round tube, M15head thread 40-200mm.

Straight regular flip-top cap

Diameter 30mm-40mm, suitable for Φ30-40mm round tube, M15head thread 40-200mm.

Fat-angled flip-top cap

Diameter 30mm-40mm, suitable for Φ30-40mm round tube, M15head thread 40-200mm.

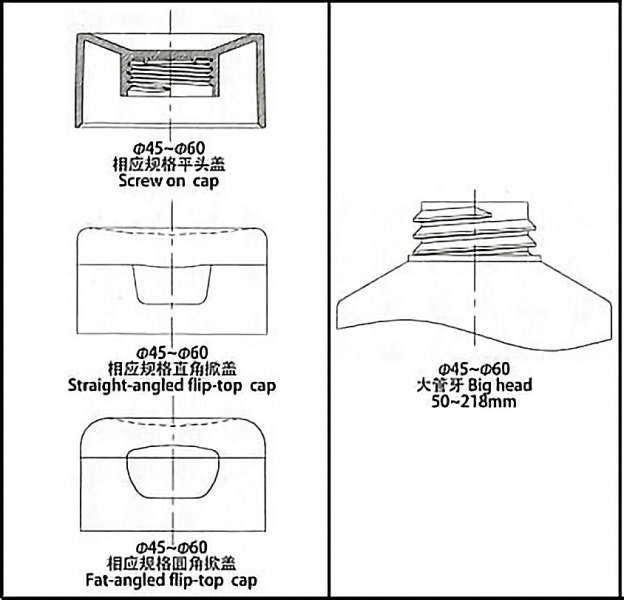

Screw on cap

Diameter 45mm-60mm, suitable for Φ45-60mm round tube, big thread 51-218mm.

Straight-angled flip-top cap

Diameter 45mm-60mm, suitable for Φ30-40mm round tube, big thread 51-218mm.

Fat-angled flip-top cap

Diameter 45mm-60mm, suitable for Φ30-40mm round tube, big thread 51-218mm.

Above 3 items are quite popular on plastic cosmetic tube item.

With cosmetic pump head item

Cosmetic tube with airless pump head item are quite popular on these days.

With the massager particular application head item

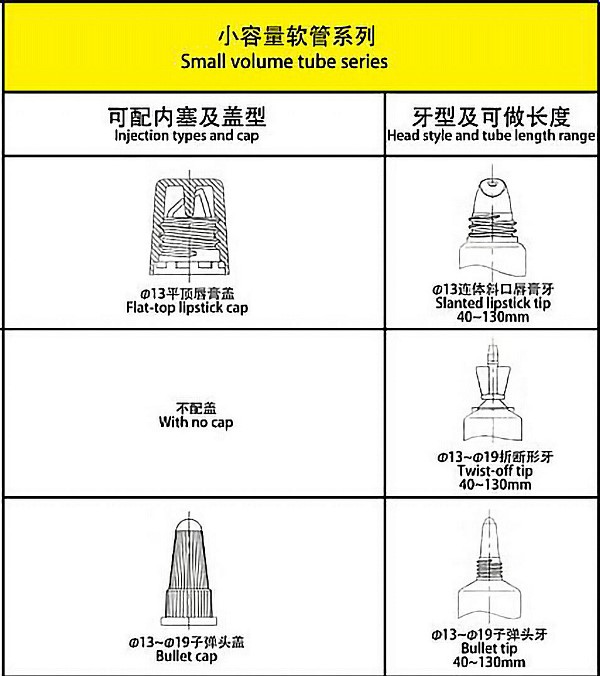

The closure style for small volume tube option

flat-top lipstick cap

Diameter 13mm, for Φ13mm slanted lipstick tip

with no cap

Diameter 13mm-19mm, for twist-off tip 40-130mm tube

bullet cap

Diameter 13mm-19mm, bullet tip 40-130mm tube

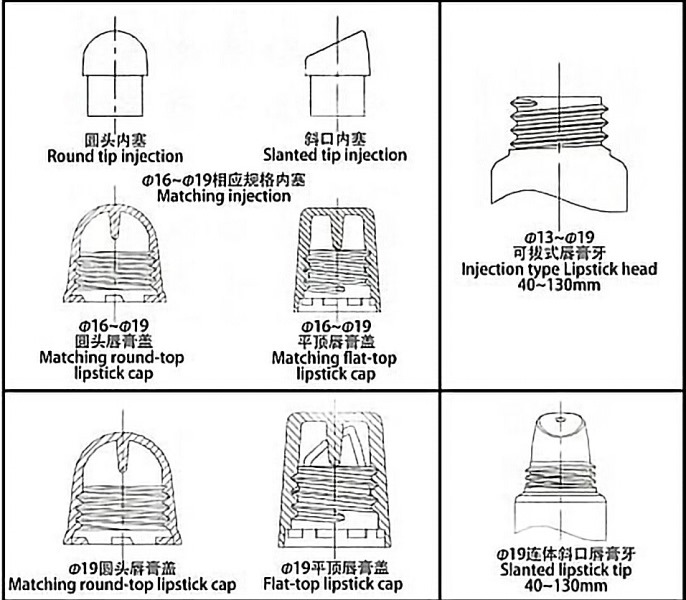

lipstick style cap

1>round tip applicator with matching round-top lipstick cap for Diameter 16mm-19mm tube

2>slanted tip applicator with matching flat-top lipstick cap for Diameter 16mm-19mm tube

3>flat-top lipstick cap or round-top lipstick cap for for Diameter 40mm-130mm slanted lipstick tip tube

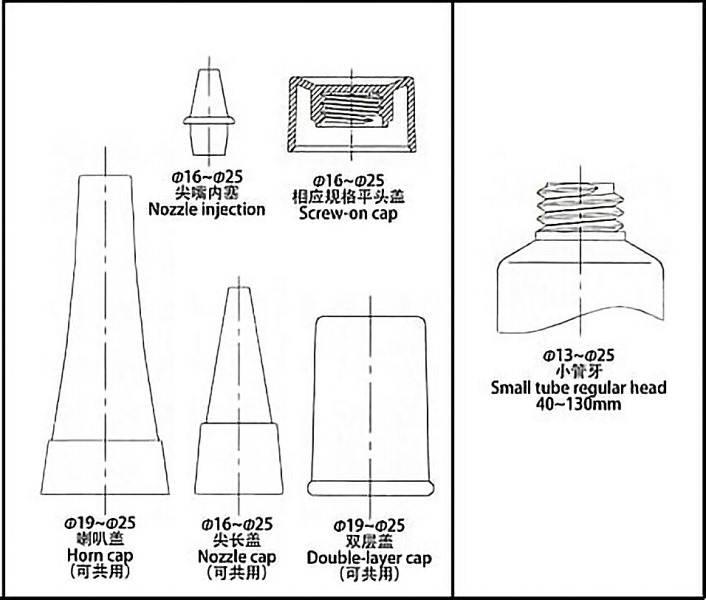

nozzle style cap

1>horn cap for Diameter 16mm-25mm tube

2>nozzle cap for Diameter 16mm-25mm tube

3>double layer cap for Diameter 19mm-25mm tube

4>screw-on cap for Diameter 19mm-25mm tube

If you like this article, you can download the pdf file on bellow to unlock by sharing.

-250x250.jpg)

-250x250.jpg)

-250x250.jpg)

Leave a Comment