Explanation of foaming bottle packaging and its benefits II. Advantages of foaming bottle packaging A. Saves product and money B. Environmentally friendly C. Easy to use III. Types of foaming bottle packaging A. Plastic foaming bottles B. Glass foaming bottles IV. Features to consider before purchasing foaming bottle packaging A. Pump type B. Bottle volume and shape C. Durability D. Customization options V. How to use foaming bottle packaging A. Mixing the solution B. Attaching the pump C. Priming the pump VI. Frequently asked questions about foaming bottle packaging A. How do I maintain the foaming bottle pump? B. Are foaming bottle pumps interchangeable with regular pumps? C. Can I use any liquid with a foaming bottle pump? D. How can I prevent clogs in the foaming bottle pump? E. How can I choose the right foaming bottle packaging for my product? VII. Conclusion

Recap of the benefits and uses of foaming bottle packaging

Foaming Bottle Packaging Supplier for purchasing options

The Ultimate Guide to Foaming Bottle Packaging

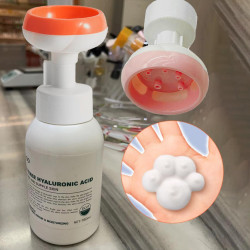

Foaming bottle packaging has gained popularity in recent years due to its numerous benefits. Businesses have embraced the use of foaming bottles to package their products, from soaps and shampoos to household cleaners. In this guide, we will explore everything you need to know about foaming bottle packaging, its advantages, types, features, and how to use it.

Advantages of foaming bottle packaging

Saves product and money

Foaming bottle packaging dispenses products in a controlled and efficient manner. The pump dispenses the product as a foam, reducing the amount of product used per usage. This reduction can save money in the long run by making each container of product last longer.

Environmentally friendly

Foaming bottle packaging is also an environmentally friendly option. Due to the dispensing of the foam, less product is used, and less waste is created. This reduction of waste helps in preserving the environment.

Easy to use

Foaming bottle packaging is simple and easy to use. The pumps come pre-adjusted and can be used with minimal instruction. They make product dispensing quick, easy, and mess-free.

Types of foaming bottle packaging

There are two main types of foaming bottle packaging: glass and plastic.

Plastic foaming bottles

Plastic foaming bottles are a popular option for foaming bottle packaging. They are lightweight, shatter-resistant and come in a variety of colors. They are also cost-effective and have the benefit of being recyclable.

Glass foaming bottles

Glass foaming bottles are another option for foaming bottle packaging. They are eco-friendly and recyclable, offering an environmentally friendly alternative to plastic bottles. However, glass bottles may be more delicate and are not always ideal for all applications.

Features to consider before purchasing foaming bottle packaging

When purchasing foaming bottle packaging, there are several features to consider.

Pump type

The type of pump is a crucial feature for foaming bottle packaging. Different pump types can dispense different foaming effects, ranging from a thick foam to a fine mist.

Bottle volume and shape

The volume and shape of foaming bottle packaging are essential features to consider. It’s essential to choose based on the size and shape of the product, which will dictate the bottle you need.

Durability

Durability is an important feature to consider when selecting foaming bottle packaging. The container should withstand the product it contains, the storage, and the shipping.

Customization options

Customization options are an excellent feature for foaming bottle packaging. It allows for the logo, color, size, and shape to match your product branding.

How to use foaming bottle packaging

The process of using foaming bottle packaging is simple.

Mixing the solution

The first step in using foaming bottle packaging is mixing the solution. Add the desired amount of the product and water to the bottle, leaving enough space for the pump.

Leaving the enough space for pump, this is very important when It come to create foaming. per our experience, the enough space should be about 40-50ml.

Attaching the pump

Attach the pump to the bottle by twisting it onto the neck. Ensure that the pump is securely attached to the bottle.

Priming the pump

Prime the pump by pushing it down a few times until the foam starts to dispense. Once the foam is dispensed, it’s ready for use.

Frequently asked questions about foaming bottle packaging

How do I maintain the foaming bottle pump?

To maintain the foaming bottle pump, spray alcohol into it after every use. This will help prevent clogs in the pump and ensure it lasts longer.

Are foaming bottle pumps interchangeable with regular pumps?

Foaming bottle pumps are not interchangeable with regular pumps. They are designed to dispense foam and have different specifications than standard pumps.

Can I use any liquid with a foaming bottle pump?

Foaming bottle pumps are designed to work with certain liquids. Not all products can be dispensed using a foaming bottle pump. Check the product or the pump’s specifications before use.

How can I prevent clogs in the foaming bottle pump?

Clogging can be prevented by spraying alcohol into the pump after every use. If the pump still clogs, disassemble the pump and clean it using warm soapy water.

How can I choose the right foaming bottle packaging for my product?

Factors such as the product’s characteristics, consumer preference, and container material should be considered when evaluating which foaming bottle packaging to choose.

Conclusion

Foaming bottle packaging is an excellent option for businesses that are environmentally conscious and considering economics. With its vast benefits, such as saving money and preserving the environment, it's an option that should be considered when researching packaging options. The various types, features, and uses of foaming bottle packaging make it a versatile option for many products.

Foaming Bottle Packaging Supplier for purchasing options

FAQs

Why is foaming bottle packaging environmentally friendly?

Foaming bottle packaging is environmentally friendly because it saves the product and reduces waste by dispensing foams instead of liquids. This means you use less product per usage, saving money and reducing waste.

Can I use a different product than the one recommended by the manufacturer?

It is best to use the product specifically recommended by the manufacturer to ensure the foaming bottle pump dispenses it effectively. Different product formulations may not be compatible with the foam pump, leading to poor performance.

Can I use the foaming bottle packaging for hot liquids?

Foaming bottle packaging is designed to work best with room temperature or cold products. Using hot or boiling liquids can damage the pump mechanism and affect the reliability and performance of the packaging.

How do I choose the right pump for my products?

When selecting the right foaming bottle pump for your products, consider the desired foam texture and consistency required. Thick foams may require pumps with large orifice sizes, while fine mists may require pumps with a narrower orifice size. It is also important to make sure the pump is compatible with the product being dispensed.

What’s the difference between a foaming bottle pump and a regular pump?

The main difference between a foaming bottle pump and a regular pump is the foaming mechanism. A foaming bottle pump dispenses a foam rather than a liquid, made possible by its mechanism that mixes air with the product. Regular pumps are used for liquid product dispensing and have different specifications.

Internal links: